Hydropneumatic Systems: How They Work and Where They're Used

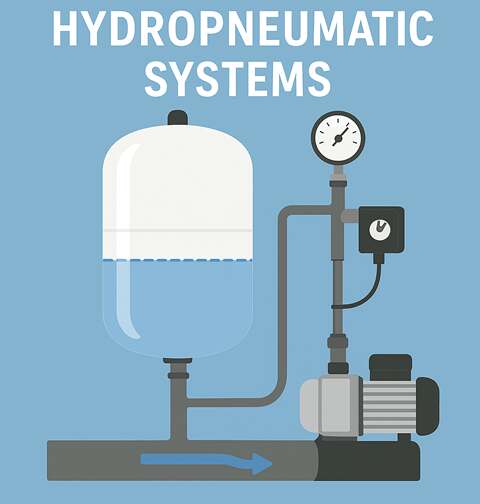

In plain terms, a hydropneumatic system uses both water (hydro) and compressed gas (pneumatic) to control pressure and flow. The usual goal is to store energy and smooth out the delivery of fluid so pumps don't cycle on and off constantly. The heart of many installations is the hydropneumatic tank, often fitted with a rubber bladder or diaphragm separating the water from the compressed air. When the pump runs, it compresses the air and stores pressurized water; when demand occurs, that stored energy pushes water into the network until pressure drops and the pump restarts.

A compact physical analogy: the tank is like a shock absorber for water pressure, it soaks up the peaks and releases steady flow during valleys.

Core components, briefly

- Pump: centrifugal or submersible, sometimes labeled a hydropneumatic pump or hydro pneumatic pump, moves water into the tank and system.

- Hydropneumatic tank: bladder or diaphragm type, sometimes called a hydro pneumatic pressure tank.

- Pressure switch and gauge: set cut in and cut out points so the pump starts and stops at desired pressures.

- Check valve and isolation valves: prevent backflow and allow service.

- Air compressor or precharge valve: used to set or replenish the gas side pressure in some tanks, especially when the bladder loses charge.

- Pressure relief: safety device to avoid overpressure.

Technically, the trapped air follows compressible fluid laws; a classic relationship often quoted is Boyle’s law, P1V1 = P2V2, which helps explain how pressure and volume trade off as water enters or leaves the tank.

How it actually operates, step by step

- Pump fills the system and pushes water into the hydropneumatic tank.

- Incoming water compresses the air cushion inside the tank, raising system pressure.

- When system pressure reaches the pump’s cut- out setting, the pump stops.

- A downstream demand (open faucet, irrigation valve) lowers pressure; the compressed air pushes water out of the tank to meet demand.

- When pressure falls to the cut in setting, the pump restarts and the cycle repeats.

Because the tank stores a buffer of pressurized water, pump starts per hour are reduced, mechanical wear is lower, and users notice smoother pressure at fixtures.

Where they are used

Hydropneumatic systems appear across many sectors, including:

- Domestic well systems: replacing large atmospheric tanks, a hydro pneumatic pump tank delivers pressurized household water with fewer pump cycles.

- Booster pump systems: to raise city mains pressure for multi story buildings; here a hydro pneumatic booster pump combination prevents short cycling.

- Irrigation and agriculture: steady pressure for sprinklers and drip lines, especially when multiple zones run intermittently.

- Fire protection: certain fire suppression designs use pressure vessels to ensure immediate water delivery.

- Industrial process systems: pressure stabilization for production lines, hydraulic forming, and more.

- Automotive and rail: hydropneumatic suspension systems (the classic Citroën system and similar designs) use fluid and gas for ride control and leveling.

- Marine and specialty machinery: where space is limited but a high- power, compact pressure buffer is needed.

Advantages and trade offs

Pros include reduced pump wear, less electrical cycling, diminished water hammer, and improved user comfort. Tanks are compact relative to the stored energy they provide. On the flip side, bladder failures, lost precharge, or improper sizing can lead to short cycling, reduced lifespan, and interrupted service. Tank and pump selection matters: a small hydropneumatic tank set for high frequency duty will not perform as well as one sized correctly for flow and expected run times.

Practical tips and maintenance

- Precharge setting: a common practice is to set tank precharge a couple of psi below the pump cut in pressure; this helps ensure the bladder and pressure switch operate in sync.

- Inspect the bladder: if the tank loses its air cushion, you may need to recharge the gas or replace the bladder.

- Watch pump cycles: excessive short cycling means the tank is under sized, the precharge is wrong, or there’s a leak.

- Air compressor for hydropneumatic tank: some systems include a small compressor to maintain air charge automatically; this is handy in large installations.

- When comparing costs, evaluate lifecycle expense: energy usage, maintenance, replacement parts and the benefit of fewer pump starts.